Chain Sizing

Rode Length/ Scope

The ratio of the length of rode to the water depth is known as the scope. Anchoring with sufficient scope brings the direction of strain close to parallel with the seabed. In general the longer your rode the better. 10:1 Scope is preferable in windy conditions. It’s recommended that an average cruising boat carries at least 300 feet of rode, which will allow for 10:1 scope in 25 feet of water (5 feet allotted for free-board height). This will ensure that most of the time you can anchor with 10:1 Scope.

Many cruisers find that 10:1 scope is a nice compromise between rode length/weight and maximizing anchor holding power.

It is generally accepted that in a storm situation we strive to put out 10:1 scope, but why? See below how anchors maximum holding power varies with changing scope:

| Scope | % Max Hold Power | Degrees from Horizontal |

|---|---|---|

| 2/1 | 10 % | 30 |

| 3/1 | 40% | 19.5 |

| 4/1 | 55% | 14 |

| 6/1 | 70% | 9.5 |

| 8/1 | 80% | 7 |

| 10/1 | 85% | 5 |

| 20/1 | 89% | 2.8 |

Rode Strength:

In the 1950s ABYC developed data for the strength required of anchors, capstans, rode and cleats. Tom Hale, a past ABYC technical director, stated it is reasonable to apply the figures in the table below to the entire anchor system.

Comparing to field data we concluded that this table represents the worst shock loads expected on a chain-only anchor rode. By including a line rode or an adequately designed snubber you can reduce the shock loads by a factor of 3, reducing or eliminating the wear and damage from these loads. This is why using a snubber is so important. However, when sizing anchor rode it is still important to consider loads as stated in the table. In a storm we can not 100% rely on the integrity of a snubber. Should the snubber fail, the integrity of the rode should be sufficient to handle the loads alone.

The ABYC Horizontal Working Load (lbs) Table

| Wind Speed (Knots) | Anchor Class | Boat Length – Feet | ||||||

|---|---|---|---|---|---|---|---|---|

| 20 ft | 25 ft | 30 ft | 35 ft | 40 ft | 50 ft | 60 ft | ||

| 15 | Lunch Hook | 90 | 125 | 175 | 225 | 300 | 400 | 500 |

| 30 | Working | 360 | 490 | 700 | 900 | 1200 | 1600 | 2000 |

| 42 | Storm | 720 | 980 | 1400 | 1800 | 2400 | 3200 | 4000 |

| 60 | Violent Storm | 1440 | 1960 | 2800 | 3600 | 4800 | 6400 | 8000 |

When sizing your gear for cruising ensure that the Working Limit Load (WLL) of your rode is higher than the loads expected in a storm. Sizing the working rode for a hurricane might not be practical but sustained winds greater than 40 knots are commonly encountered by cruising vessels on anchor. Sizing for such conditions is a reasonable way to approach the problem and is the basis for our recommendations.

WLL: Working Limit Load /Safe Working Load (SWL)/Normal Working Load (NWL) is the load that the rode can safely support without fear of breaking. Usually marked on the equipment by the manufacturer and it is often 1/3 to 1/4 of the Minimum Breaking Strength (MBS) for chain and 1/10 to 1/12 the Minimum Breaking Strength (MBS) for rope.

Chain Rode

Manufacturers:

This is the list of the common chain manufacturers that sell in USA

USA:

ITALY:

CHINA:

CERTIFYING BODIES: (the Standards from different certifying bodies some time overlap)

- NACM – National Association of Chain Manufacturers (US Chain manufacturers make chain to NACM specs)

- ISO – International Standards Organization

- DIN

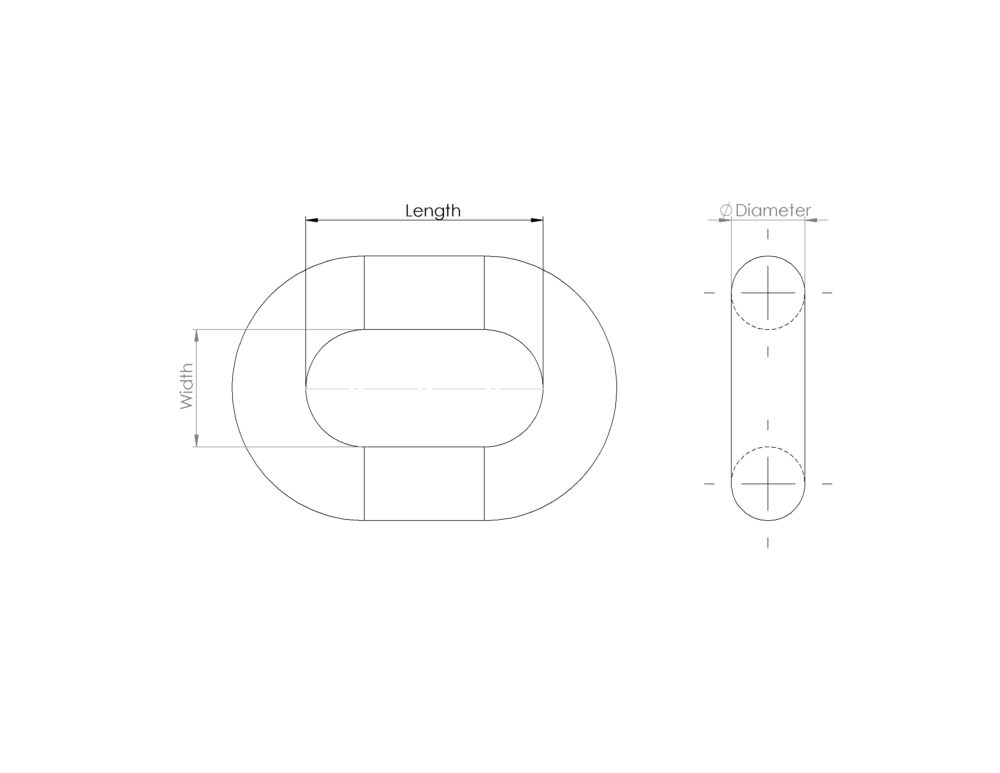

Chain Link Geometry:

- Proof Coil Grade 30: Proof coil chain is a general purpose chain, frequently used for light duty tow chains, tie down chains and logging chains. Links are longer, thus the chain is lighter than BBB and G4 dimensioned chain for equivalent length.

| Proof Coil Chain (Usually Grade 30) | Chain Size (in) | Wire Diameter (in) | Inside Length (in) | Inside Link Width (in) | Inside Link Length (mm) | Inside Width (mm) |

| 1/4 | 0.279 | 1 | 0.507 | 25.4 | 12.9 | |

| 5/16 | 0.342 | 1.1 | 0.507 | 27.9 | 12.9 | |

| 3/8 | 0.404 | 1.23 | 0.62 | 31.2 | 15.7 | |

| 1/2 | 0.512 | 1.5 | 0.822 | 38.1 | 20.9 | |

| 5/8 | 0.628 | 1.9 | 1.02 | 48.3 | 25.9 | |

| 3/4 | 0.779 | 2.2 | 1.1 | 55.9 | 27.9 |

- BBB: Short, compact links. The short link makes the chain more flexible and ideally suited for a windlass, usually made in Grade 30 only.

| BBB Grade 30 | Chain Size (in) | Wire Diameter (in) | Inside Length (in) | Inside Link Width (in) | Inside Length (mm) | Inside Width (mm) |

| 1/4 | 0.274 | 0.87 | 0.43 | 22.1 | 10.9 | |

| 5/16 | 0.328 | 1 | 0.5 | 25.4 | 12.7 | |

| 3/8 | 0.392 | 1.09 | 0.62 | 27.7 | 15.7 | |

| 1/2 | 0.509 | 1.34 | 0.75 | 34.0 | 19.1 |

- G4 Dimensioned chain : Most common specification for Hi Test Chain sold in the USA.

| G4 Test Chain | Chain Size (in) | Wire Diameter (in) | Inside Length (in) | Inside Link Width (in) | Inside Length (mm) | Inside Width (mm) |

| 1/4 | 0.274 | 0.845 | 0.4 | 21.5 | 10.2 | |

| 5/16 | 0.33 | 1.03 | 0.49 | 26.2 | 12.4 | |

| 3/8 | 0.399 | 1.22 | 0.58 | 31.0 | 14.7 | |

| 7/16 | 0.467 | 1.4 | 0.66 | 35.6 | 16.8 | |

| 1/2 | 0.51 | 1.59 | 0.77 | 40.4 | 19.6 |

| DIN 766 Dimensions (Grade 70 and Grade 80 chain are usually DIN 766) | Chain Size (mm) | Wire Diameter (mm) | Inside Length (in) | Inside Width (in) | Inside Length (mm) | Inside Width (mm) |

| 6 | 6 | 0.73 | 0.31 | 18.5 | 8 | |

| 7 | 7 | 0.87 | 0.35 | 22 | 9 | |

| 8 | 8 | 0.94 | 0.39 | 24 | 10 | |

| 10 | 10 | 1.10 | 0.55 | 28 | 14 | |

| 11 | 11 | 1.22 | 0.55 | 31 | 14 | |

| 13 | 13 | 1.42 | 0.71 | 36 | 18 |

| ISO4565 – (ACCO) | Chain Size (in) | Wire Diameter (in) | Inside Length (in) | Inside Link Width (in) | Inside Length (mm) | Inside Width (mm) |

| 1/4 | 0.279 | 0.87 | 0.441 | 7.1 | 22.1 | |

| 5/16 | 0.332 | 1.11 | 0.505 | 8.4 | 28.2 | |

| 3/8 | 0.404 | 1.226 | 0.576 | 10.3 | 31.1 |

- Grade L Chain (AS2321-2006) Grade 30 Chain specified for the Australian Market

| Grade L Chain | Chain Size (mm) | Wire Diameter (mm) | Inside Length (in) | Inside Link Width (in) | Inside Length (mm) | Inside Width (mm) |

| 6 | 6 | 0.71 | 0.30 | 18 | 7.5 | |

| 8 | 8 | 0.94 | 0.39 | 24 | 10 | |

| 10 | 10 | 1.18 | 0.49 | 30 | 12.5 | |

| 13 | 13 | 1.54 | 0.64 | 39 | 16.3 |

- Stainless Steel Chain: Imported and US Made stainless steel chain is available made to various NACM, ISO, DIN specifications . Stainless Chain is available in several grades: 304, 316, Duplex. Duplex stainless steel chain is the strongest option available in Grade 60 and is more corrosion resistant than 304, 316 stainless steel and is ussually made to G4 and DIN776 dimensional standards.

Chain Grade:

National Association of Chain Manufacturers

The chain grade is based on the nominal stress in the link at the design breaking force strength. (It is calculated by taking the minimum breaking force load and dividing by two times the nominal cross sectional area of the link.) Another words the higher the grade the stronger the chain. Chains Grade 80 and above are considered to be ok for overhead lifting. These higher grades are usually not easily accessible. Most common grades for anchor chain are Grade 30 (BBB & Proof Coil) & Grade 40 (HT)

Chain Strength Table:

Note: the WLL (Wroking load) for chain is usually defined ¼ of the UBS (Ultimate Breaking Strength) expressed in pounds for all chain types except G4, Grade 40 HTChain has the WLL defined as 1/3 of the UBS. It is unclear why the WLL definition is different for Grade 40 chain. To make the comparison easier we defined Working Load below for all chain as 1/4 of the UBS.

| Chain Size | ||||||

| 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | ||

| Proof Coil Grade 30 | 5200 | 7600 | 10600 | 14800 | 18000 | UBS |

| 1300 | 1900 | 2650 | 3700 | 4500 | WLL | |

| BBB Grade 30 | 5200 | 7600 | 10600 | 14800 | 18000 | UBS |

| 1300 | 1900 | 2650 | 3700 | 4500 | WLL | |

| Stainless Steel 316 | 6280 | 9600 | 14200 | 21600 | 26000 | UBS |

| 1570 | 2400 | 3550 | 5400 | 6500 | WLL | |

| G43 High Test | 7800 | 11700 | 16200 | 21600 | 27600 | UBS |

| 1950 | 2925 | 4050 | 5400 | 6900 | WLL | |

| Grade 60 Duplex | 8400 | 14160 | 22480 | 37090 | UBS | |

| 2100 | 3540 | 5620 | 9272.5 | WLL | ||

| Grade 70 | 12600 | 18800 | 26400 | 35000 | 45200 | UBS |

| 3150 | 4700 | 6600 | 8750 | 11300 | WLL | |

Main focus should be placed on sizing the chain for the expected loads. Using higher grades of chain can offer some weight saving however. For example, 300 feet of 3/8 BBB weighs 468 lbs vs. 300 feet of 5/16 G4 HT which weighs 310 lbs and has higher strength. Thus if taking 160 lbs off the bow is considered important, using higher grade chain definitely has its advantages. Another issue is matching the gypsy on the windlass to the chain size and type. A windlass gypsy designed for 5/16″ High Test chain will not work on 5/16″ BBB, which has shorter, more compact links. Many windlasses have a selection of gypsies, which can be Special Ordered to fit the rode on your boat. Often availability and the cost of the right gypsy enter the calculus of which chain size and type is right for you. It is important to remember not to compromise on the strength of the system when making such decisions.

Chain Sizing Recommendations:

| Boat Size | 0- 14 feet 1,000 lbs | 14-20 feet 5000 lbs | 20-30 feet 11,000 lbs | 30-35 feet 15,000 lbs | 35-40 feet 20,000 lbs | 40-45 feet 40,000 lbs | 45-50 feet 50,000 lbs | 50-60 feet 60,000 lbs | 60-70 feet 70,000 lbs | 70-90 feet 110,000 lbs |

|---|---|---|---|---|---|---|---|---|---|---|

| Chain BBB, Proofcoil | 1/4 | 1/4 | 5/16 | 5/16 | 3/8 | 3/8 | 7/16 | 7/16 | 1/2 | 5/8 |

| Chain HT | 1/4 | 1/4 | 1/4 | 5/16 | 5/16 | 3/8 | 3/8 | 7/16 | 7/16 | 1/2 |

How Much Chain:

It’s recommended that an average cruising boat carries at least 300 feet of chain, which will allow for 10:1 scope in 25 feet of water (5 feet allotted for freeboard height). This set up will ensure that most of the time you are anchored on chain and reduce the likelyhood of rode failure.